AC Electromagnetic Yoke

- Choice of constant level AC or variable intensity, pulsed HWDC for surface or sub-surgace flaw detectability.

- Solid state circuity for infinitely variable (stepless) potentiometric adjustment of DC magnetic field.

- Articulated legs to suit differing component contours.

- Interpole distance adjustable from 0 to 300 mm.

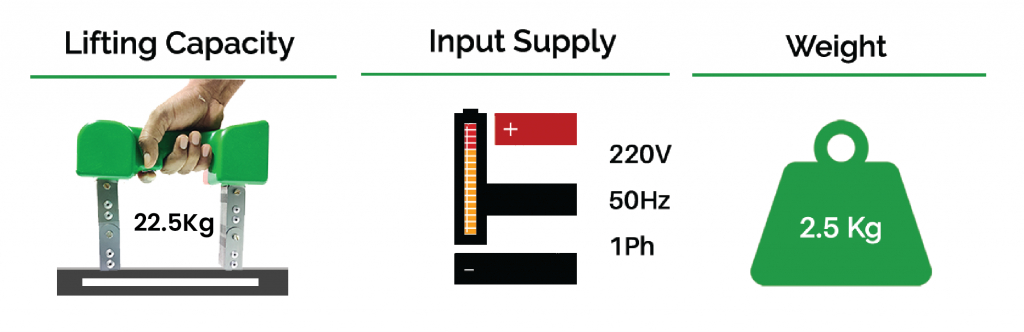

- Low power consumption. Current draw at 220V, 1 Phase supply – only 2Amps.

- Extremely strong and intense magnetic field for superior sensitvity.

- Portable & light weight – only 3.5 Kgs.

- Can be used for AC Demagnetisation too.

- No risk of sparking or ‘hot spots’ on the job.

- No current flows through the component being tested.

Principles of Operation:

When the yoke is energised, an intense magnetic field is created between the legs. This field can best be described as a multiplicity of invisible line of magnetic force extending across the gap between the legs.As the yoke is applied to the ferromagnetic component, the magnetic circuit is closed and the field enters the part making its passage between the legs at and below the surface. A crack across this field cuts the magnetic circuit, the crack sides become opposite poles of a magnet and a leakage field occurs in the air above the crack. Mangetic Particles are attracted by this leakage field and indicate the location of the flaw.

A.C. Magnetisation

- Creates a surface field which only detects surface cracks.

- Particularly useful for inspecting thick and irregular sections for surface defects such as fatigue cracks.

D.C. (Pulsed) Magnetisation

Use of Half Wave D.C. Magnetisation creates a pulsing magnetic field with penetrates the work piece and detects surface and subsurface (Slightly) cracks. Pulsing improves particle mobility and sensitivity. Can be used for dry and even wet method.

Product Properties

- NDT Type: Magnetic Particle Testing

Applications

Ideal Application: Demanding environments, Field testing, In-service inspections, Spot inspections, Weld inspection

Defect Examples: Fatigue cracks, Grinding cracks, Inclusions, Laps, Quenching cracks, Seams, Shrink cracks, Tears, Welding slag

Approvals / Confirms

- ASME BPVC

- ASTM E1444

- ASTM E709

Please fill the form

ZChem expert will provide you product details

Reviews

There are no reviews yet.