Custom-Series

Custom Built Magnetic particle Equipment

ZChem manufactures Custom Built Bench Equipment as per customer Request.

ZChems has the capability to manufacture MPI (Magnetic Particle Inspection) Bench Equipment tailored to specific customer requirements. MPI Bench Equipment is used for non-destructive testing (NDT) processes to detect surface and subsurface flaws in ferromagnetic materials. These flaws could include cracks, inclusions, or other defects that could compromise the integrity of the material.

SKU:

Custom-Series

Categories: Equipment(MPI), Magnetic Bench Equipment, Magnetic Particle Inspection

Related products

ZM-Series

Mobile Magnetizing MPI Equipment | ZChem® ZM-Series

At ZChem®, we recognize that not all components can be moved for magnetic particle inspection (MPI). That’s why we offer versatile, high-performance mobile magnetizing solutions designed to bring the testing station directly to the part.

ZM-Series: Long Cable Output for Large-Scale Inspections

For applications requiring long-distance MPI testing, the ZChem® ZM-Series is built to handle extended cable lengths, making it ideal for inspecting large components such as power generator parts. Designed for maximum efficiency and precision, this unit ensures consistent and accurate defect detection even when the power source is positioned far from the test piece.

With industry-leading technology and robust performance, ZChem®’s mobile MPI solutions deliver unmatched convenience and accuracy for non-destructive testing (NDT) professionals worldwide.

For more details or customised solutions, contact ZChem today.

ZChek-9 Black

Oil-Based Visible Magnetic Particle Suspension

ZChek-9 Black is a black dry powder formulated to be used in wet method Magnetic Particle Inspection to detect discontinuities on light colored surfaces for optimum color contrast. Generally used for Non fluorescent Magnetic Particle inspection in Fabrication, castings & Bright Bars. 9 black may be suspended in either ZChek-801 cart oil or in water. When water as a vehicle use conditioning agents ZChek-WA9.ZChek-F18W

Water based Fluorescent Magnetic Particle

ZChek-F18W is a Brown Colored water based Magnetic Particle Powder designed to be fluorescing Bright Yellow- Green under UV Light. ZChek-F18W consists of ultra-high sensitivity particles for detection of very fine discontinuities in Ferromagnetic materials. Using the state-of-the-art encapsulation technology, ZChek-F18W is manufactured to exhibit excellent properties (High permeability, low retentivity, high mobility and optimum particle distribution) required for high sensitive fluorescent MPI process. Special additives in F18W provide excellent particle mobility in water medium and avoid flash rusting of parts.ZChek-WA 9

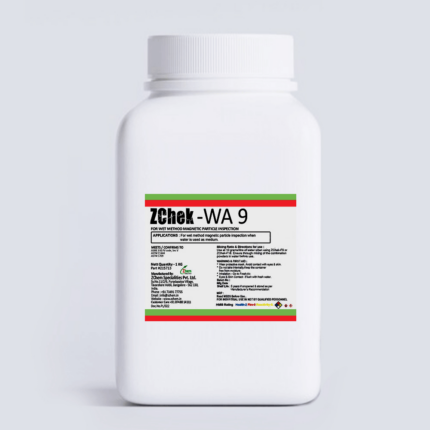

Water Conditioner

ZChek-WA 9 is a water conditioner used as wetting agent in magnetic particle inspection when water is used as a carrier. WA9 can be used with either ZChek-F9 or ZChek-F18 at recommended concentration to get desired results while using water as a carrier medium. WA9 has wetting agents, corrosion inhibitors and antifoaming agents which enhances in wet method magnetic particle testing.ZC-9

AC Electromagnetic Yoke

AC electromagnetic yoke, ergonomically designed to improve productivity and reduce operator arm and wrist fatigue. The yoke generates a strong AC magnetic field for the detection of surface indications during magnetic particle testing. Lightweight with an ergonomic grip and trigger, the ZC-9 is designed for the rugged demands of field inspection. Featurin a rugged cord and an isolated trigger switch; the ZC-9 is easily serviceable.Technical Specifications

- Input supply – 220V, 50Hz, 1 Ph

- Distance across poles – 0 to 300 mm

- Lifting power Approx. 4.5Kg. at 100mm spacing

- Yoke Weight 2.5 Kgs approx.

- Controls On/Off Switch.

MD-Series

Multidirectional Benche Equipment

Most versatile wet magnetic benches with multi-directional capabilities with each output offering AC, HWDC or 1-phase FWDC output. The MD-Series multi-directional magnetic bench offers Alternating Current, Half Wave Direct Current and 1-phase Full Wave Direct Current for time-saving multidirectional magnetization which can find defects in all orientations with one mag-cycle. The two outputs (contact and Flux Flow coil) each offer AC, HWDC or 1-Phase FWDC, and are independently adjustable to balance the magnet field intensity. MD-Series magnetic benches are available in three models: ZC-230MD, ZC-450MD and ZC-600MDZM-Series -bkup-280425

Mobile Magnetizing MPI Equipment | ZChem® ZM-Series

At ZChem®, we recognize that not all components can be moved for magnetic particle inspection (MPI). That’s why we offer versatile, high-performance mobile magnetizing solutions designed to bring the testing station directly to the part.

ZM-Series: Long Cable Output for Large-Scale Inspections

For applications requiring long-distance MPI testing, the ZChem® ZM-Series is built to handle extended cable lengths, making it ideal for inspecting large components such as power generator parts. Designed for maximum efficiency and precision, this unit ensures consistent and accurate defect detection even when the power source is positioned far from the test piece.

With industry-leading technology and robust performance, ZChem®’s mobile MPI solutions deliver unmatched convenience and accuracy for non-destructive testing (NDT) professionals worldwide.

For more details or customised solutions, contact ZChem today.

Reviews

There are no reviews yet.