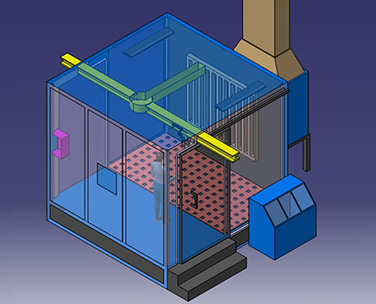

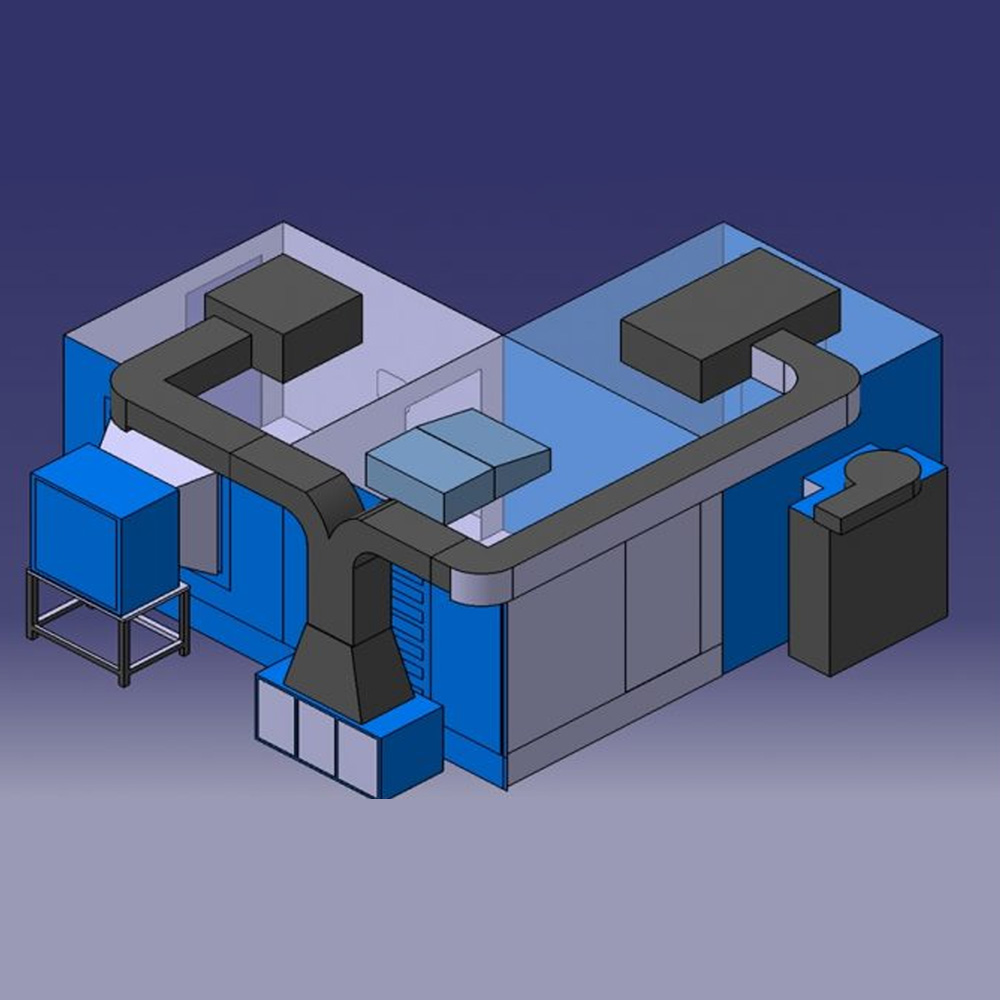

Penetrant & Washing station

Penetrant & Washing station

Penetrant & Washing station

Penetrant & Washing station

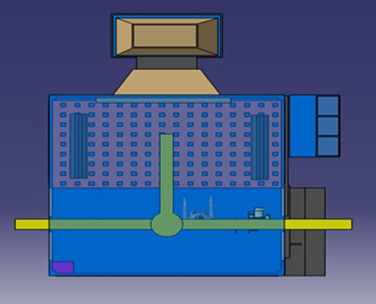

Technical Specification

- The superior stainless steel construction for better life performance.

- Protection lock for dwell time.

- The dwell times are controlled through timers/PLC.

- The digital temperature and timer control.

- Special Air water wash gun for the water wash station.

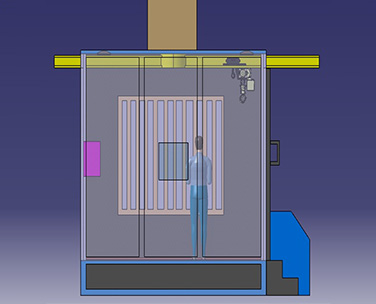

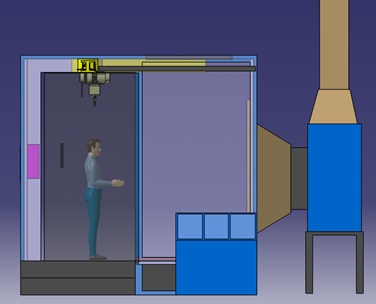

- Manual Washing of excess penetrant & Wash station is provided with Hood, white ight and UV light.

- Dry developer cloud chamber

Optional Features

- Components Loading Fixture

- All testing accessories and consumables – Meeet AMS specifications.

- Additional wire baskets for components loading.

- Ultrasonic Cleaning system for Pre-Cleaning’s Requirements.

- Post Emulsified FPI Systems are made to Customer’s Requirements.

- Monorail System with Balancers for processing heavier Components.

Please fill the form

ZChem expert will provide you product details

Reviews

There are no reviews yet.